SCREEN-PRINTING

TRADITIONAL SCREEN PRINTING

Print Method

The most traditional and popular form of garment printing. The stencil of your graphic is developed onto a screen, and ink is then pushed through the mesh to transfer your graphic onto your garment. Each color requires a separate screen, but it produces high quality prints that will hold up for a long time. This method of printing is cost effective for large quantity orders.

Past Prints

The Process

Preparing the Screen:

Before starting the printing process, it’s essential to properly prepare the screen. This involves choosing the right mesh count and frame size based on the design and material being printed on. The screen is then coated with a light-sensitive emulsion, which will form the stencil for the design when exposed to light.

Design Creation:

Creating the design is a critical step in custom screen printing. Artists must tailor their artwork for screen printing by considering aspects like line thickness, color separation, and halftone patterns. Once the design is finalized, it is transferred onto the prepared screen using techniques such as drawing directly, using film positives, or digital transfers.

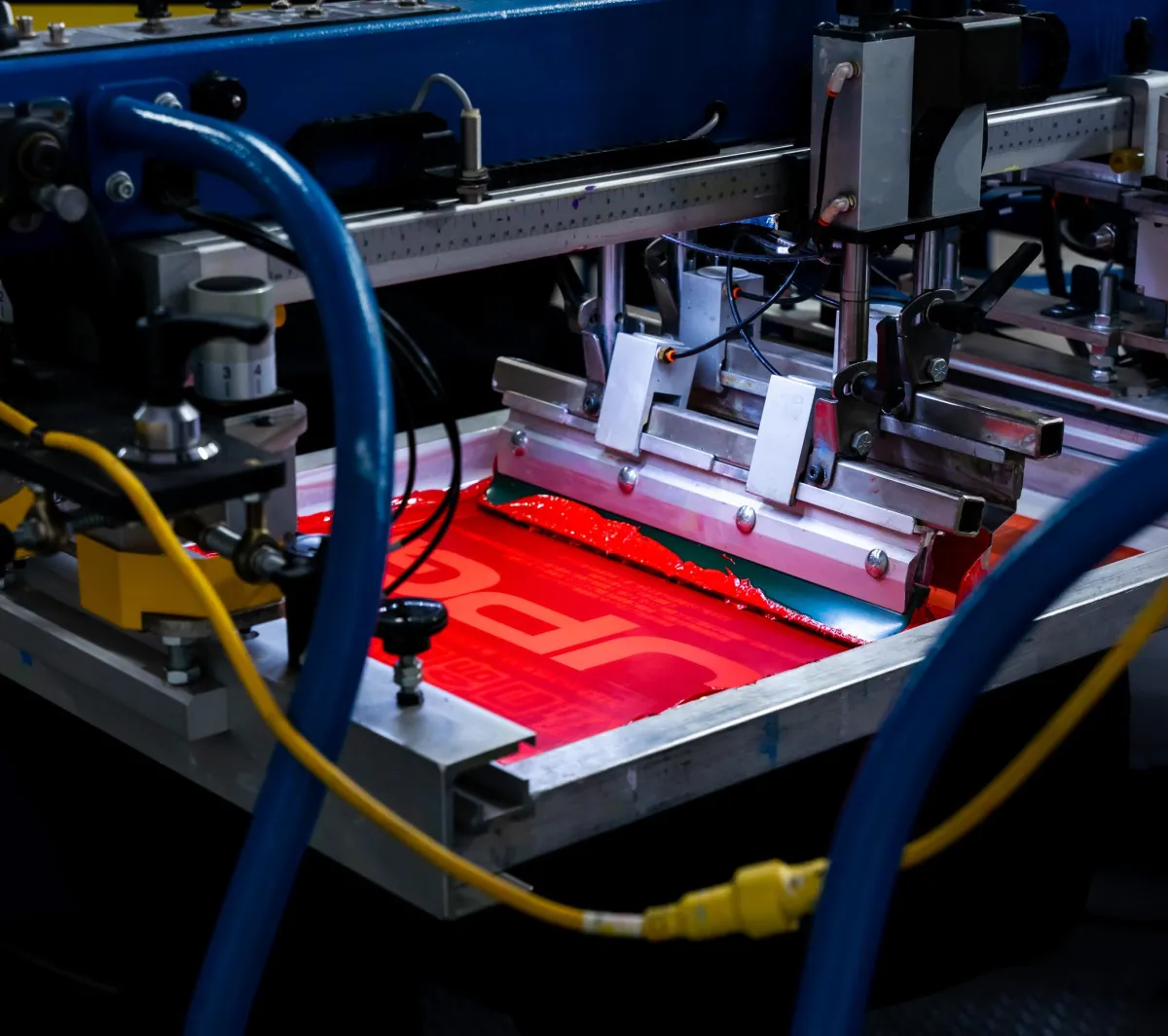

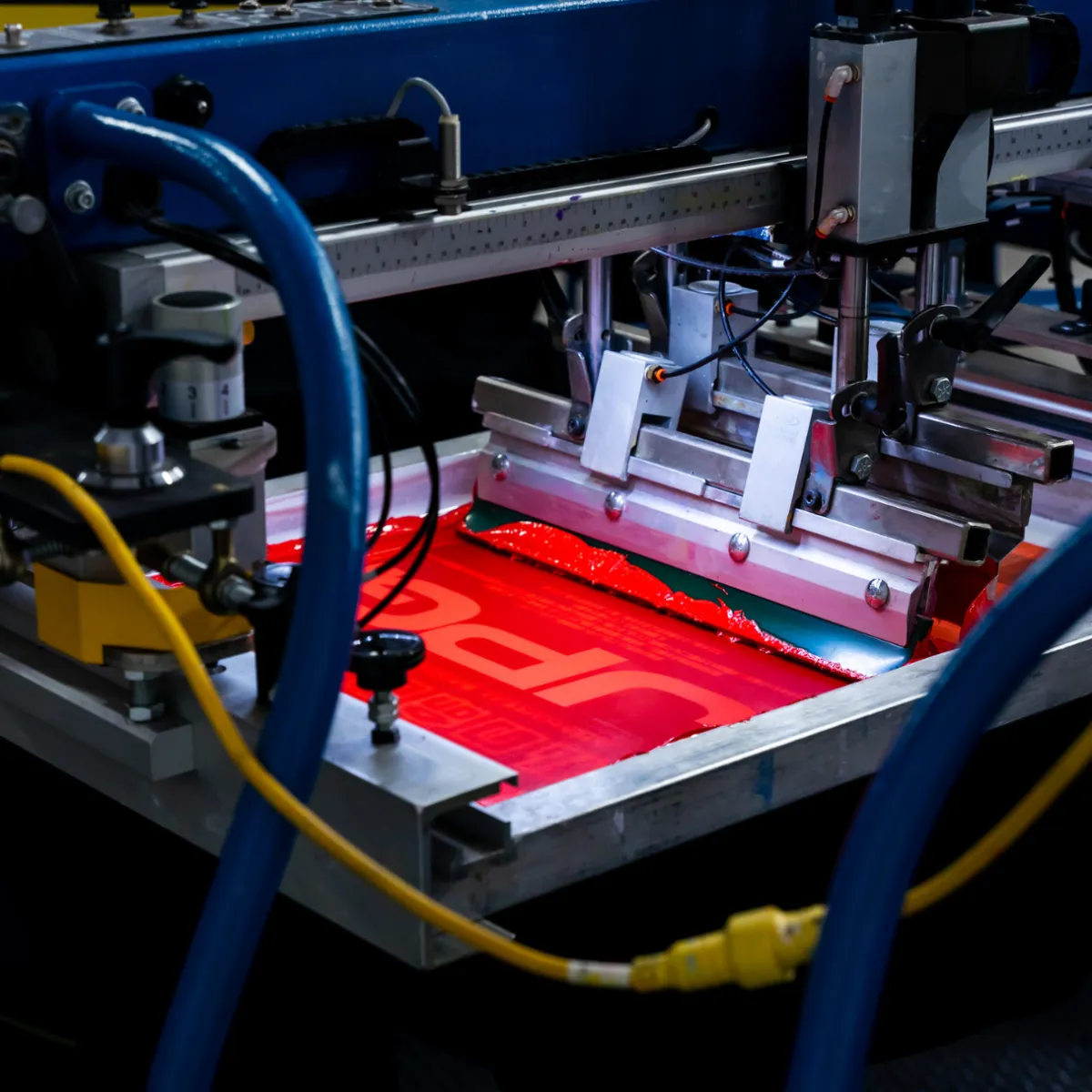

Printing the Design:

During the printing phase, ink is pushed through the stencil onto the material using a squeegee. The selection of ink is crucial for achieving the desired results, as various inks differ in opacity, flexibility, and color richness. The way the squeegee is used significantly influences the print’s quality and consistency.

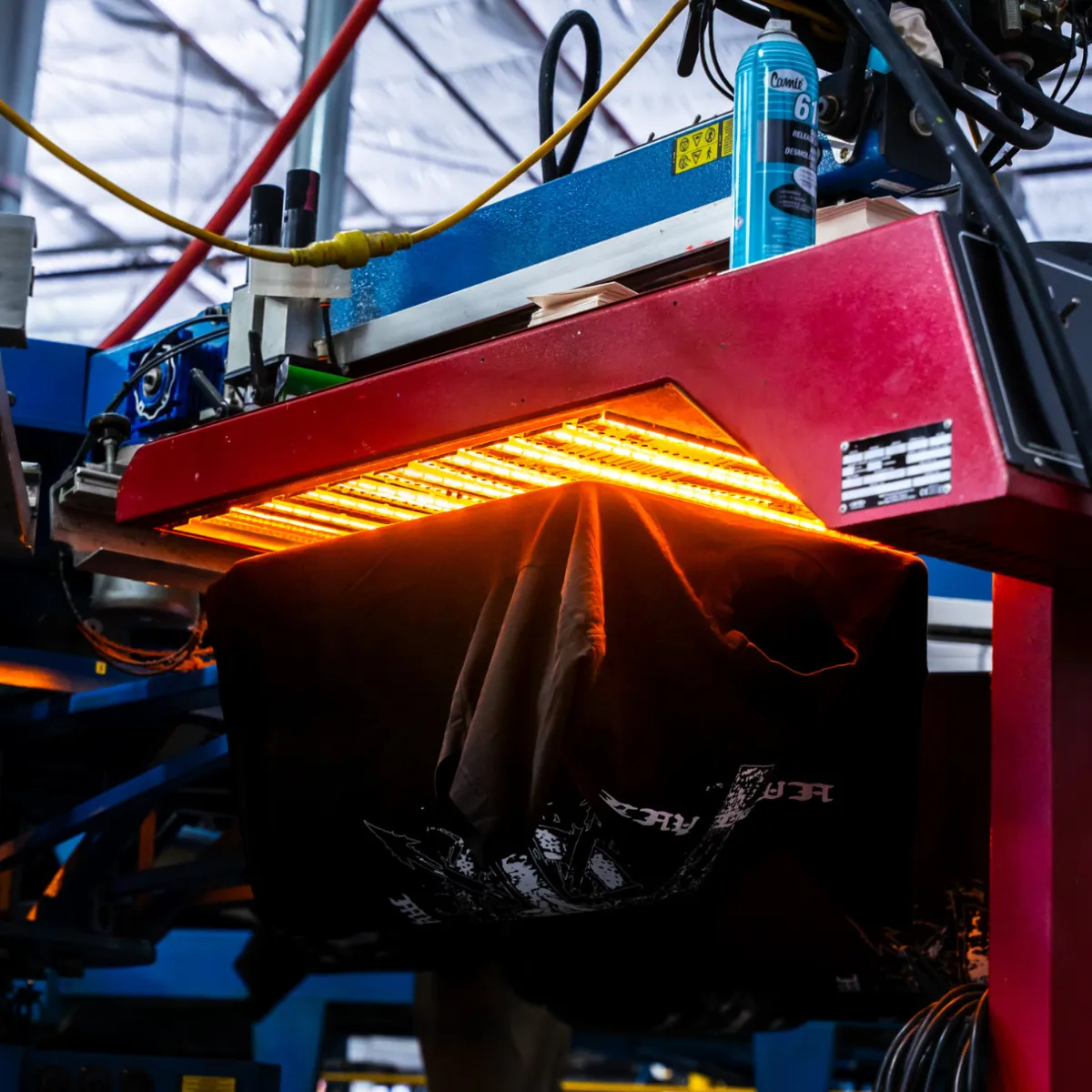

Curing and Final Touches:

Once printed, the ink needs to be cured to ensure its durability and resistance to washing. This is typically done through heat curing, using tools like conveyor dryers or flash curing units. After curing, the print is carefully inspected for imperfections before being cleaned and readied for delivery or further processing.

Benefits of Custom Screen Printing

Benefits of Custom Screen PrintingDurability and Longevity:

Screen printing is renowned for its long-lasting quality, with prints that hold up well to repeated washing and wear without fading or peeling. This makes it an excellent option for producing durable designs on clothing and other items.

Versatility:

Screen printing is compatible with a wide array of materials and surfaces, including cotton, polyester, plastics, and metals. This adaptability allows for a vast range of creative projects, from apparel and accessories to promotional products and signage.

Cost-Effectiveness for Large Volumes:

One of the main advantages of screen printing is its cost-effectiveness for large-volume orders. The setup costs are spread across the entire print run, making the cost per unit significantly lower than methods like digital or sublimation printing.

Vibrancy and Quality:

The technique produces vibrant, high-quality prints with sharp details and rich colors. The ink’s thick layers penetrate the substrate, resulting in designs with excellent opacity and saturation.

Applications of Custom Screen Printing

Apparel and Merchandise:

Custom screen printing is extensively used in the apparel industry for creating branded t-shirts, hoodies, caps, and more. Its durability and versatility make it a popular choice among clothing manufacturers and designers.

Promotional Products:

Screen printing is also widely used for creating promotional items like bags, pens, mugs, and keychains. Its ability to print on various materials makes it ideal for producing branded merchandise for marketing campaigns and events.

Art and Home Décor:

Screen printing is a popular technique in the art and décor world. Artists use it to create limited-edition prints, posters, and home décor items. Its ability to capture intricate details and vivid colors makes it a preferred method for producing high-quality art prints.

Tips for Successful Custom Screen PrintingSelecting the Right Material:

Choosing the right substrate is key to achieving the best print results. Factors such as fabric type, surface texture, and color should all be considered when selecting materials for your screen printing projects.

Design Considerations:

Ensure that design elements such as line thickness, font size, and color choices are carefully planned for clarity and impact in the final print. Simplify overly complex designs and avoid intricate details that may not transfer well onto the material.

Collaborating with a Professional:

For complex or large-scale projects, it’s often beneficial to work with an experienced screen printer who can guide you through the design, material selection, and production processes. Their expertise can help ensure your project is executed successfully.